White Paper: Finite Element Analysis, Part 1

Historically, product designers relied on basic calculations to approximate the capability of a design. However, these calculations were limited and could only validate relatively simple design shapes, so product development relied on iterative real-life testing and prioritized previously proven and standardized designs. Due to the increased complexity, complex shapes and more challenging material properties were rarely used.

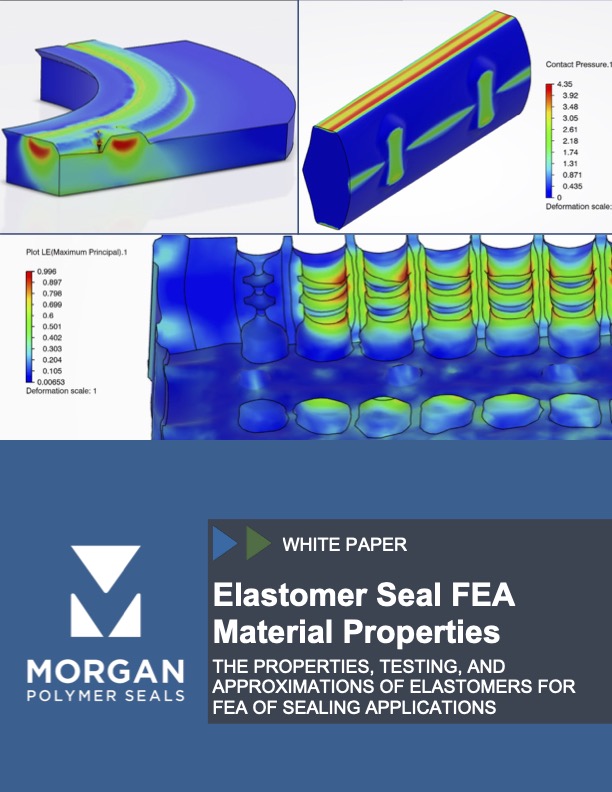

To validate critical seal designs in the modern era, many industries have adopted Finite Element Analysis (FEA) to reduce the need for extensive testing and reduce the timeline of the product development cycle.

Before any FEA work can be started, though, a thorough understanding of the elastomer’s material properties is required.

We’re pleased to offer you another technical White Paper, written by our very own Design Engineer, Thomas Morgan. Here are just a few of the key insights you’ll learn gain inside the pages:

Why Finite Element Analysis a critical step in designing quality rubber gaskets and seals

Best practices for Material Testing

How to work with Approximation Equations

This white paper is part one of a three-part series on the FEA process for rubber elastomer seals, so check back soon for more technical insights into this critical technology.

Elastomer Seal FEA Material Properties

Download our white paper on Elastomer Seal FEA Material Properties by clicking the button below.