Successful Seal Design: Finite Element Analysis to Validate Design

Engineer Thomas Morgan, performing FEA with computer simulation

by Thomas Morgan, Design Engineer

Design validation is a critical step to developing a successful gasket or seal. At this stage, a design engineer confirms that the final product will function properly within the sealing application

Because the validation stage can resolve design issues ahead of production, validation often saves time and money for manufacturers and their customers.

Historically, product designers relied on basic calculations to approximate results. These calculations were limited, however, to validating relatively simple design shapes and not ideal for validating complex shapes, or parts with more challenging material properties.

To validate critical seal designs for automotive applications, savvy engineers have adopted Finite Element Analysis (FEA).

What is FEA?

FEA is a computer simulation that predicts how a part will react to real-world conditions, such as temperature, force, pressure, and displacements.

In our blog post about the seal design process, we outlined our eight-stage design process. FEA is the fifth stage in our process, preceded by 1) discovery and design input; 2) design concept development; 3) component positional stackup, and 4) calculations. The more detail we collect about the product and its application during the first four stages, the more robust and accurate FEA will be.

FEA Process

To start FEA, we upload a CAD model of the seal and its mating surfaces into a software simulation program. We have adopted the Abaqus Solver for its capabilities in dynamic and non-linear analysis required for seal design.

Inside the program, the seal is represented by points in space so we can accurately measure how each point responds to the various forces that the seal will encounter within its application. These measurements ultimately help us to understand if the seal design will succeed or fail.

Least Material Condition

Example of Least Material Condition simulation

FEA is run at the part’s least material condition (LMC), which is the minimum compression allowed by the assembly at room temperature. In this analysis, we measure for contact pressure, or the pressure applied by the seal’s surface in its final position. We also measure the seal’s contact patch width taken at a cross-section of the seal - a metric useful for preventing leaks due to voids and openings in the mating surfaces.

Maximum Material Condition

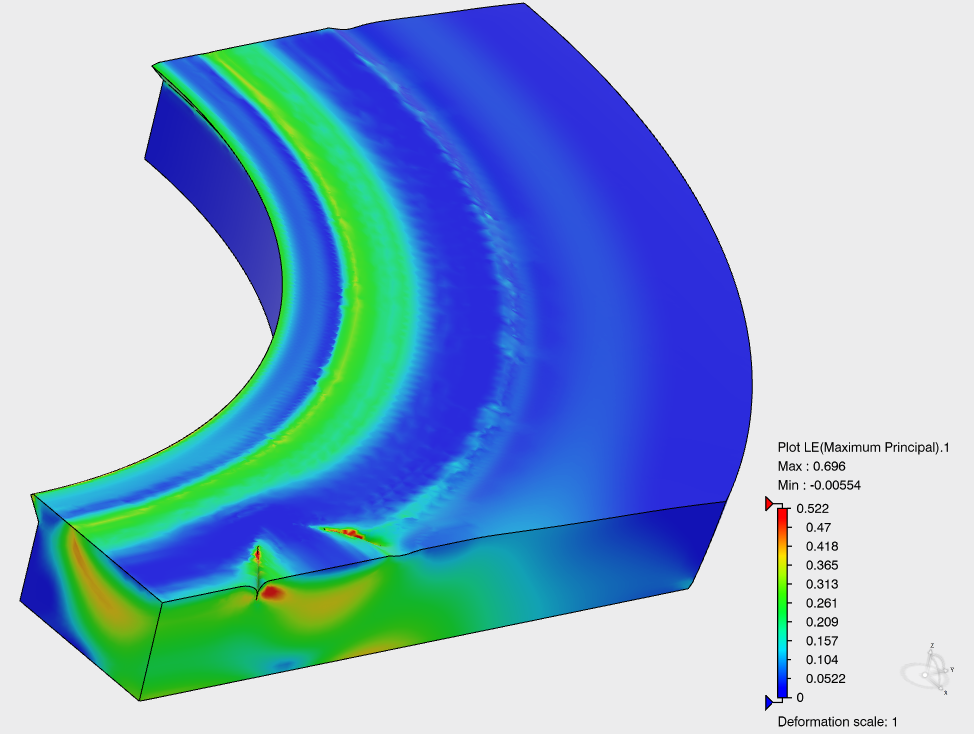

Example of Maximum Material Condition simulation

FEA is also run at the seal's maximum material condition (MMC) – which is the maximum compression allowed by the assembly at the operating temperature. From MMC, we predict the highest engineering stress and logarithmic strain to determine the strength of the material throughout the part's lifetime.

Animation of FEA simulation

FEA also predicts the reaction forces applied to the mating parts, which are the highest in the MMC condition. If the seal is between metal parts, the reaction forces help determine the maximum gap between the parts. If the seal is used on plastic or composite parts, the reaction forces are used to determine the maximum permanent deformation of the plastic parts over time.

Lastly, FEA also predicts insertion forces for seals installed into a groove, which are the highest in the MMC condition. While some applications use a mechanical press to insert the seal, other applications require a human to push the seal into its final position. For ergonomics, we run dynamic insertion simulations to determine the maximum force required.

How Long Does FEA Take?

Our engineers can turn around a relatively simple FEA report in about a week, but some designs require more time. Sometimes FEA requires additional simulation setups, such as analyzing the impact of different temperatures. In other cases, a seal might have stricter part requirements that often require multiple design iterations.

The Morgan Polymer Seals Advantage

FEA provides much-needed validation of a seal's design ahead of production, which saves time and money. That's why our expert engineers conduct thorough Finite Element Analysis to support successful seal design, prototyping, and quality manufacturing. Our in-house FEA service, combined with decades of automotive experience, are just two of the reasons we are the most trusted name in automotive gaskets, delivering 100 million parts per year to North America, Europe, and China

For more information about FEA, or to discuss your design and manufacturing needs, click the button below to contact Morgan Polymer Seals.